In the past two years, whether it's for scented candles, holiday candles, or everyday decorative candles, more and more customers have been asking the same question: Can fully refined white paraffin wax be used with soy wax? Frankly, this question itself reflects the changing market. Consumers are becoming more environmentally conscious, but factories are more concerned with production stability, transportation risks, and the final product's performance. The blend of fully refined paraffin wax and soy wax happens to be at the intersection of these two needs. Junda Wax, from the perspective of a professional manufacturer, will help you understand how to use these two most common types of wax.

I. Why are more and more candles using blended waxes?

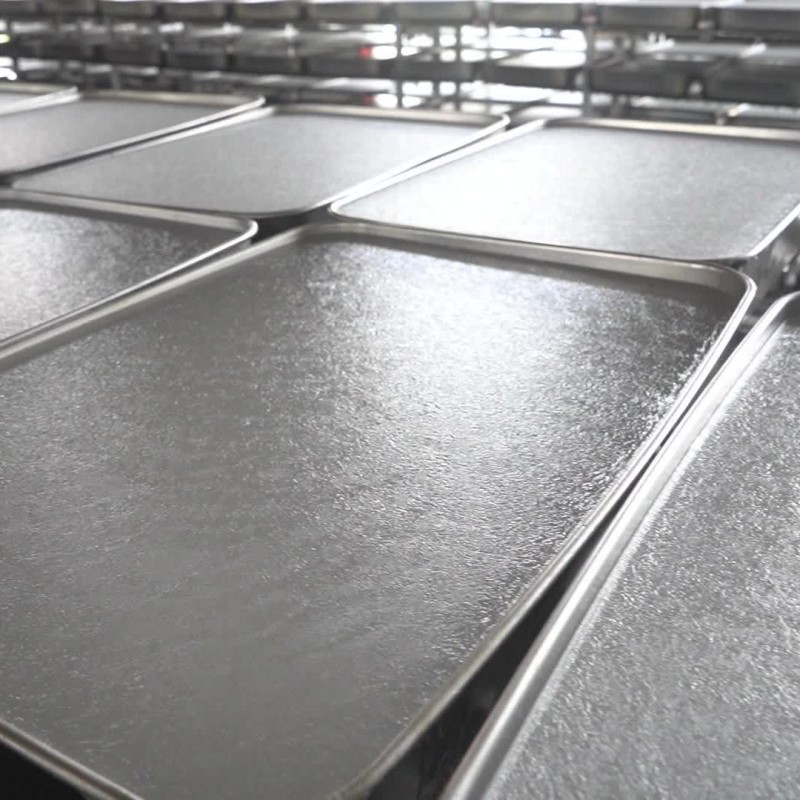

If you only look at the marketing, it's easy to think that the market has completely shifted to plant-based waxes, but anyone who has actually been in a production workshop will understand that a single wax material is difficult to solve all problems. Soy wax is naturally sourced, has high market acceptance, is suitable for scented and gift candles, and is more easily perceived by consumers as environmentally friendly; however, it is relatively soft and sensitive to temperature, transportation, and storage conditions, making it risky for large-scale exports. Fully refined white paraffin wax, on the other hand, sets quickly, is highly stable, and has controllable burning performance, making it ideal for mass production. Combining these two waxes is not a compromise, but a more realistic and mature approach, which is why blended waxes are becoming increasingly common in export-oriented candle factories. Junda Wax, as a professional candle and raw material manufacturer, can provide a variety of different candle raw materials. Please feel free to inquire.

II. Are fully refined paraffin wax and soy wax truly "compatible"?

From a material perspective, fully refined paraffin wax and soy wax are completely compatible in production. As long as the melting temperature is properly controlled and the mixing is thorough, they can form a very stable blended system. The real concern is not whether they can be mixed, but the quality of the white paraffin wax. If the white paraffin wax has a high oil content and many impurities, it is easy to cause layering, sweating, or surface instability after mixing. Therefore, in actual production, almost all blended waxes use high-quality fully refined paraffin wax, not semi-refined or low-grade paraffin wax. This is especially crucial for export orders. Junda Wax's white paraffin wax products exported to multiple countries and regions are primarily fully refined white paraffin wax.

.jpg)

III. What are some common "golden ratios" for different applications?

Many customers are most concerned about whether there is a ready-made ratio that can be used directly. Strictly speaking, there is no single ratio that suits all products, but in a large number of export projects, some very mature and stable ranges have indeed emerged. The most common is a combination of 70% paraffin wax and 30% soy wax. This ratio works very well in scented container candles, ensuring both molding and burning stability while meeting market expectations for plant-based waxes. If you want to further emphasize the plant-based wax concept, some European and American customers will choose 60% paraffin wax plus 40% soy wax, but this requires higher demands on the wick and manufacturing process. Conversely, in high-temperature regions or long-distance sea freight projects, 80% paraffin wax plus 20% soy wax is safer, with lower transportation and storage risks.

Different application scenarios require different ratios. Junda Wax has many years of production and export experience and can provide customized solutions for your specific projects. We welcome you to consult with us about your project, and we will provide you with the most professional advice.

Why are more and more customers choosing "one-stop supply"?

Among our collaborating customers, many initially only purchased white paraffin wax, but later gradually switched to purchasing the entire set of materials from us. The reason is quite practical: when waxes, wicks, fragrances, dyes, and equipment come from different suppliers, it's difficult to quickly pinpoint the cause of any problems. The advantage of one-stop supply is that the formula, materials, and process are integrated, resulting in higher adjustment efficiency and more stable production. Junda Wax can not only provide fully refined paraffin wax and soy wax, but also simultaneously provide wicks, dyes, fragrances, and candle production equipment, truly helping customers transform their product ideas into stable mass production.