The material selection and meticulously verified process details of scented candles are very sophisticated. Among all wax materials, fully refined white paraffin wax has been widely used by many export-oriented candle factories not because it is "cheap" or "traditional," but because its performance in terms of stability, controllability, and large-scale production is truly difficult to completely replace.

Junda Wax, through long-term cooperation with clients in Europe, America, the Middle East, and South America, has repeatedly verified this point: no matter what concepts are trending in the market, fully refined white paraffin wax remains the most stable foundation for scented candles.

I. What is fully refined paraffin wax? Why are scented candles inseparable from it?

Fully refined paraffin wax, simply understood, is paraffin wax raw material that has undergone deep de-oiling, impurity removal, and deodorization. It is whiter in color, has a cleaner smell, contains fewer impurities, feels delicate to the touch, and has better transparency after melting. For scented candles, these seemingly basic characteristics are actually very crucial.

Many customers new to scented candles worry about whether white paraffin wax will have an odor, but true fully refined paraffin wax is almost odorless. Because it is clean enough, it does not interfere with the true scent of the fragrance. The fragrance smells exactly as it should, without being masked or mixed with the scent of the wax itself.

In Junda Wax's export projects, especially scented candle products for the EU and North American markets, fully refined paraffin wax is almost always part of the basic formula and is rarely completely replaced.

II. What is the actual performance of fully refined paraffin wax?

Once in the actual production process, the advantages of fully refined paraffin wax become very intuitive. First, in the wax melting stage, it heats up quickly and melts evenly, avoiding problems such as localized overheating or residual hard lumps, which is very convenient for factories using wax melting tanks and automatic wax pouring machines.

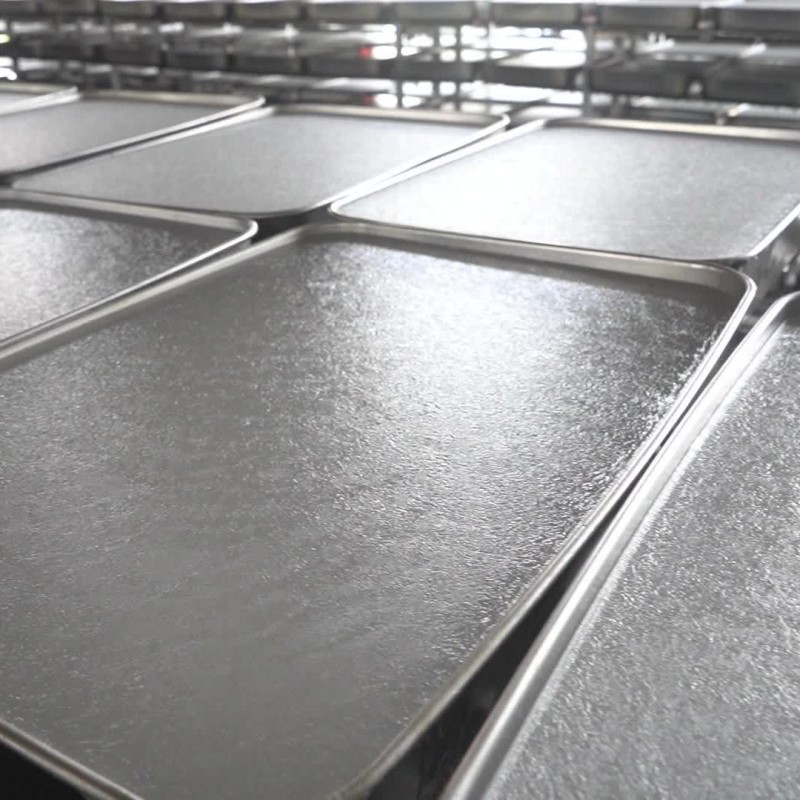

In the molding stage, the stability of fully refined white paraffin wax is also very evident. The resulting scented candles have a flatter surface, finer crystallization, and more even color distribution, greatly reducing common problems such as shrinkage, cracking, and surface blooming. This is especially important for the appearance of finished products, particularly glass jar candles and container candles.

During combustion, the flame of fully refined white paraffin wax is relatively stable, does not flicker erratically, and does not easily produce black smoke. This is especially important for export customers, as many countries have very strict requirements regarding burning performance and user experience. Therefore, Junda wax has always used fully refined paraffin wax, which burns stably without producing black smoke, making it very environmentally friendly and suitable for customers with strict environmental requirements.

III. Why does fully refined paraffin wax diffuse fragrance more effectively?

In scented candles, whether the fragrance is released effectively is not only a matter of the fragrance itself, but also the structure of the wax plays a decisive role. Fully refined paraffin wax has a relatively uniform molecular structure, allowing the fragrance to disperse more thoroughly, and the release is more direct and stable when heated.

Many customers find in actual testing that with the same proportion of fragrance added, the cold and hot fragrance performance of fully refined white paraffin wax systems is clearer. This is especially true for common winter scents such as cinnamon, vanilla, pine, and apple; if the wax is too heavy, the fragrance is less likely to diffuse.

This is why fully refined white paraffin wax is still widely used in high-end and holiday scented candle products, rather than being completely replaced by plant-based waxes.

Why are more and more customers choosing one-stop supply?

As the scented candle market becomes more competitive, more and more customers are finding that purchasing raw materials separately can no longer meet their production needs. What truly affects efficiency and product stability is whether the entire system is compatible.

Junda wax not only provides fully refined white paraffin wax and various other waxes, but also offers a one-stop supply of wicks, dyes, fragrances, and candle production equipment such as melting pots, pouring machines, and cooling tables. Many overseas customers have developed from small-batch trial production to stable exports by cooperating with our one-stop production manufacturer. For customers who truly want to make scented candles a long-term export product, the question is not whether to use fully refined paraffin wax, but how to use it, how to combine it, and how to maximize its advantages.

Junda wax has many years of experience in the white paraffin wax and candle manufacturing industry. In addition to paraffin wax, we can also provide you with a series of products such as wicks, dyes, and candle manufacturing machines. If you have any needs for related products, please feel free to contact us via email. We have a dedicated service team to handle your inquiries.