Colored candles may seem like they simply have added color, but those who have actually produced them know that adding color doubles the difficulty of candle making. Uneven color, surface discoloration, color differences after cooling, color changes during burning, and even cracking and collapsing edges due to the dye affecting crystallization—these problems are almost all related to wax selection and wax usage methods.

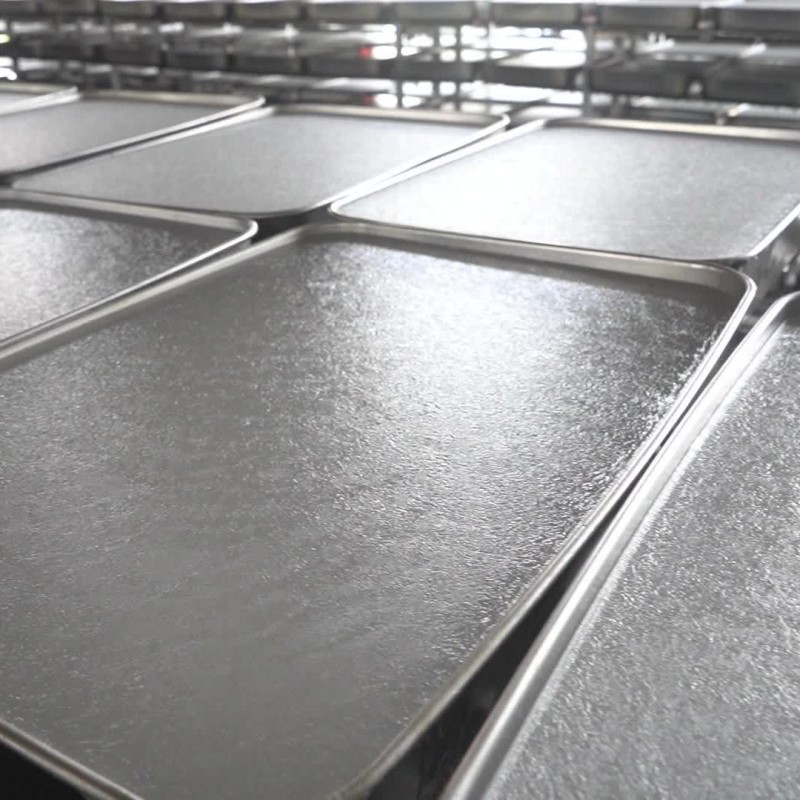

Among many wax materials, Fully refined white paraffin wax has always been one of the most stable and easiest-to-control basic materials for colored candles. Junda wax, drawing on practical production experience, will discuss: how to effectively use fully refined paraffin wax to truly improve the stability of colored candles.

Why is processing colored candles more difficult?

Adding colored dyes to white candles inherently changes the crystallization method, cooling rate, and internal structure of the wax. The darker the color and the higher the amount of dye added, the more pronounced the interference with the wax system. If the wax itself has many impurities and unstable oil content, the problems will be infinitely magnified by the color. This may not be obvious in white candles, but once they are made into red, blue, or dark green, surface defects immediately become apparent. This is why the requirements for the base wax in colored candles are definitely higher than those for ordinary white candles. Junda wax, as a professional candle manufacturer, can produce both white and colored candles.

Why is fully refined paraffin wax more suitable for colored candles?

Fully refined white paraffin wax undergoes deep refining, resulting in low impurity content and a very light base color. It won't compete with the dye for color, nor will trace impurities cause localized color abnormalities. This is a very important prerequisite for colored candles that require precise color presentation.

Fully refined white paraffin wax also has better batch-to-batch consistency. For export-oriented candle factories, consistency in color across different batches is often more important than the results of a single batch. Stable wax material is the foundation for reproducible colors. Junda wax can provide a complete set of machinery and candle materials for candle production, making your colored candles more suitable.

Choosing the right melting point is the first step to stable colored candles.

Many color problems appear to be "dye mixing issues," but the root cause is actually in the choice of melting point. Waxes with lower melting points cool quickly, and the color is easily "pushed" during the crystallization process, resulting in color streaks or patches; waxes with higher melting points crystallize more evenly, which is more conducive to stable color distribution. This sensitivity to melting point is especially pronounced in columnar colored candles.

In actual production, we usually recommend fully refined paraffin waxes with different melting point ranges based on the candle shape, color depth, and production environment, rather than using the same type across the board.

Wick selection also affects the final appearance of the color.

Many people only focus on the wax and dyes, but ignore the wick. In fact, the burning state of the wick directly affects whether the candle surface color is uniform and whether there are burn marks.

If the wick is too thick, the flame will be too large, and colored candles are prone to localized overheating during burning, leading to darkening or discoloration; if the wick is too thin, it may not burn completely, affecting the overall performance.

In colored candle projects, we usually include the wick in the testing scope, rather than just looking at the wax itself.

Export-oriented colored candles prioritize long-term stability.

During the process of exporting to multiple countries and regions, we found that overseas customers' requirements for colored candles are not just about good-looking colors. Temperature differences during transportation, storage time, and display cycles all test the stability of the candles.

Fully refined white paraffin wax performs more controllably in these aspects and is easier to pass relevant testing requirements such as REACH and RoHS. This is why many export-oriented colored candle factories ultimately return to fully refined paraffin wax as their main system.

Colored candles are never as simple as adding color to white candles. They require higher standards for wax purity, melting point range, cooling control, and dye compatibility.

The reason why fully refined paraffin wax has become the mainstream choice for colored candles is not because it is high-end, but because it is stable, reproducible, and scalable. For factories that want to make colored candles for the long term, especially for the export market, this is a time-tested choice. Welcome to contact Junda Wax for the latest information and best prices.