Container candles and pillar candles, when it comes to wax selection, essentially follow two different sets of logic. Using the wrong wax can lead to minor issues like poor appearance, or more serious problems such as unstable burning, cracking, and collapsing, especially in export markets where these issues are magnified. Many candle manufacturers initially struggle not because of a lack of technical skill, but because they haven't fully understood the compatibility of different waxes. Junda Wax, from the perspective of a professional paraffin wax and candle manufacturer, will explain why these two types of candles require different waxes.

Container Candles and Pillar Candles Have Fundamentally Different Needs

From an appearance standpoint, container candles are burned within a container, while pillar candles stand on their own. The wax in container candles is essentially a dependent material; it doesn't need to bear weight or maintain its shape. Its most important characteristics are adhering to the container walls, creating a beautiful melt pool, and releasing fragrance effectively. The wax in pillar candles, however, must be a structural material; it must support its own shape from molding and transportation to burning.

As a professional candle manufacturer, Junda Wax can recommend different paraffin waxes and suitable manufacturing methods based on your specific needs.

Container Candles

The biggest problems with container candles are wax clinging to the container walls, shrinkage, air bubbles, and uneven melting after lighting. Almost all of these problems are related to wax selection. Container candles are better suited to a relatively soft wax system with controllable shrinkage. Many established formulas use white Paraffin Wax as a base, then combine it with vegetable waxes or functional waxes as needed, allowing the wax to better adhere to the inner wall of the container during cooling.

The advantages of white Paraffin Wax here are obvious: fewer impurities, clean color, and a light scent that doesn't overpower the fragrance, making it easier to control batch consistency. This is why many export-oriented scented candles ultimately return to white Paraffin Wax as the "base material." Junda Wax has recommended white Paraffin Wax to many customers in various countries and regions for their container candles, and the feedback has been consistently excellent, which is why these customers are willing to cooperate with us long-term.

Pillar Candles

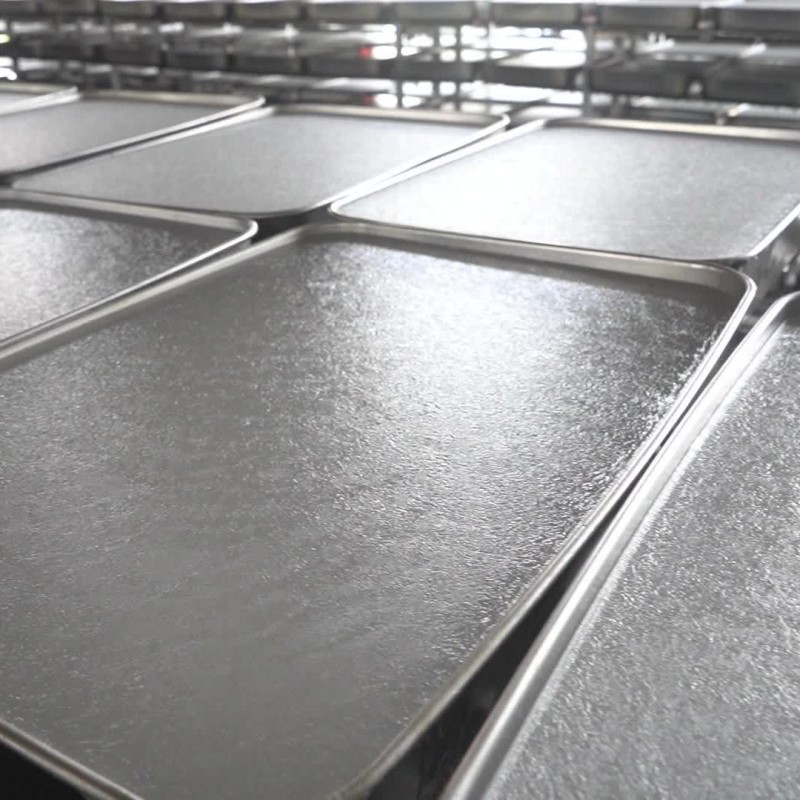

The requirements for pillar candles are almost the opposite. They don't rely on a container for support; all stability comes from the wax itself. This means it must have sufficient hardness, structural strength, and molding stability. If the wax is too soft, it's prone to deformation during transportation; if shrinkage control is poor, cracking or edge collapse can occur during demolding. This is especially true for export orders, where problems become more pronounced after long-distance sea transport and temperature fluctuations. In this scenario, white Paraffin Wax is also a very reliable option, especially grades with slightly higher melting points. It has a more uniform crystalline structure, better stability after molding, and is easier to use with automatic or semi-automatic candle production machines.

Junda Wax offers a one-stop supply solution.

In actual export projects, we have increasingly noticed that customers prefer suppliers who can provide paraffin wax, wicks, dyes, and even candle production equipment simultaneously. The reason is simple: when all materials come from the same system, many compatibility issues are resolved in advance.

Junda Wax not only provides various paraffin wax products, including fully refined and semi-refined paraffin wax, but also offers matching wicks, color systems, and equipment solutions for candle production. Whether you are making container candles or pillar candles, you can find a suitable combination within the same system. If you are making candle products, especially for the export market, instead of repeated trial and error, it's better to consider materials, processes, and equipment within the same system from the start. We have always believed that truly stable candle quality is never achieved by luck, but by understanding.