In candle production, many people initially focus on questions like which type of white Paraffin Wax to buy, what melting point to choose, and whether the oil content is high or low. However, only after starting production, mass production, and exporting will they gradually discover that one factor, although not included in the test report, affects the quality of the finished product almost every day: the cooling rate.

This problem is amplified, especially when using fully refined paraffin wax for candles. Many seemingly random occurrences of cracking, dents, and unstable burning are actually related to the cooling stage.

What is fully refined paraffin wax?

Fully refined paraffin wax is white Paraffin Wax that has been processed more thoroughly. Compared to semi-refined paraffin wax, it undergoes deeper de-oiling, decolorization, and impurity removal, resulting in lower oil content, a whiter and more stable color, and a relatively lighter odor. This is why it is widely used in the candle industry, especially in scented candles, household candles, and export candles.

Many export customers may not directly specify fully refined paraffin wax, but they will make a series of demands, such as consistent appearance, no odor, no deformation after transportation, and stable burning. These requirements ultimately point to the same choice—fully refined white Paraffin Wax. Most of Junda Wax's stable orders from customers in multiple countries and regions ultimately fall into this category of white Paraffin Wax.

Why does the cooling rate affect candles?

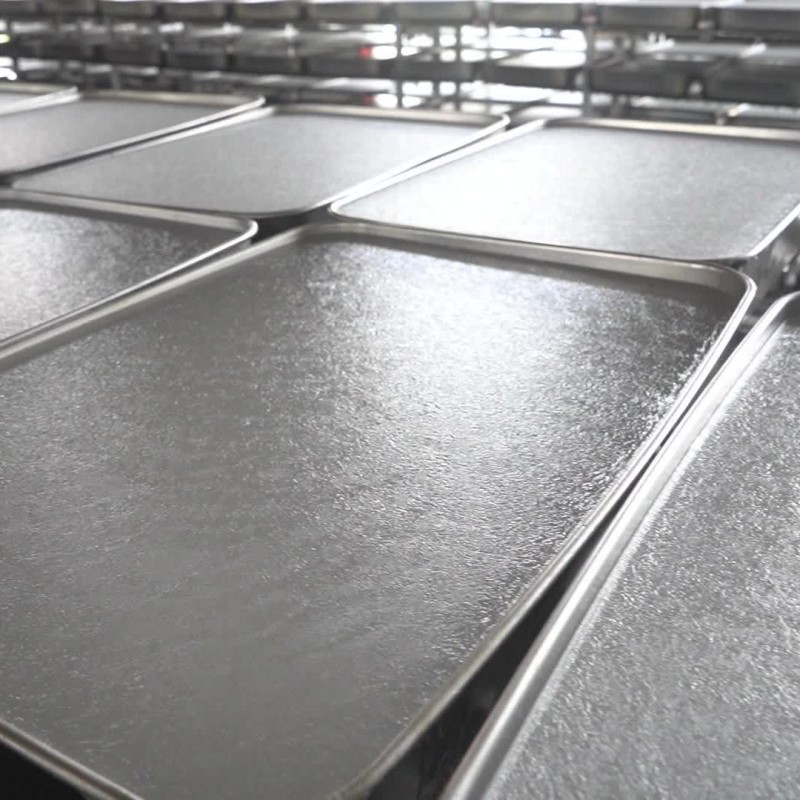

Many people think that pouring the white Paraffin Wax into the mold and letting it cool naturally is all that's needed. However, in actual production, cooling is not simply a matter of waiting, but a very real process that requires management.

The transformation of white Paraffin Wax from liquid to solid is essentially a crystallization process. The speed of cooling directly affects how the crystals are arranged—whether they are tightly and uniformly arranged, or inconsistent internally and externally. Because fully refined paraffin wax has high purity and fewer impurities, the cooling process requires stricter control, and problems are more likely to appear if the cooling conditions are not suitable.

Problems with cooling too quickly

For example, if the workshop temperature is low in winter, the molds are not preheated, or if strong wind or cold water is used to cool the candles quickly to increase efficiency. In this case, the outside of the candle may appear to solidify quickly, but the problems are often hidden inside. When cooling too quickly, the surface white Paraffin Wax solidifies first, while the interior is still slowly contracting, easily leading to internal voids or central depressions. Some candles may not show these defects immediately after demolding, but after being lit, they will exhibit uneven burning and fluctuating flame size. In more severe cases, large candles may even develop small cracks on the surface or bottom, which is a fatal flaw in export orders.

For scented candles, rapid cooling can also affect the distribution of fragrance, resulting in wax clinging to the sides of the container or unstable fragrance release.

Problems with cooling too slowly

Of course, slower cooling isn't always better. Some factories, to avoid cracking, extend the cooling time considerably, but this also brings new problems.

The most direct impact of excessively long cooling times is reduced production efficiency, which is particularly noticeable when fulfilling overseas orders with tight deadlines. Additionally, if fully refined paraffin wax is cooled slowly for a long time in a high-temperature environment, the crystals may rearrange, potentially causing slight clouding or blooming on the surface. While this may not necessarily affect usability, it makes the candles look less appealing.

What is the appropriate cooling rate?

There is no single standard answer to this question; the appropriate cooling rate is often a comprehensive result. The ideal cooling rate depends on the type of white Paraffin Wax used, the size and shape of the candle, whether dyes or fragrances are added, and the type of wick used. Manual pouring and machine production also have completely different cooling logics. Therefore, in actual cooperation, Junda Wax prefers to conduct tests with clients rather than simply selling a type of paraffin wax and ending the transaction there. The cooling rate is only meaningful when considering the materials, process, and environment together. Junda Wax has many years of export experience and can tailor the appropriate cooling rate and other aspects to your product line.

Junda Wax offers more than just fully refined paraffin wax.

In actual cooperation, we not only provide fully refined and semi-refined paraffin wax with different melting points and specifications, but also supply wicks, dyes, fragrance candle-related materials, and even candle production equipment. Whether you are a small workshop just starting out in candle making or a factory with stable export orders, our goal is to help you streamline your entire production chain, not just sell a single product. If you are looking for more than just white Paraffin Wax, but a one-stop solution from raw materials to wicks, dyes, and candle production equipment, we are happy to work with you to optimize these details step by step based on your specific products. If you are interested, please feel free to contact us.