Why do candles often experience demolding problems?

Demolding is a crucial step in candle manufacturing. Many factories producing columnar candles, mold waxes, or craft waxes frequently encounter issues such as surface scratches, breakage, and sticking to the mold. This is usually due to unstable melting points of high quality paraffin wax 58, excessively high oil content, insufficient cooling shrinkage, or improper mold temperature control—ultimately stemming from the raw materials used in candle production. Junda's Fully Refined Paraffin Wax has very low oil content, a highly uniform crystal structure, and strong thermal stability, preventing scratches and breakage during demolding.

What is the key role of Fully Refined Paraffin Wax in demolding?

High quality paraffin wax 58 undergoes extensive oil removal during production, resulting in extremely low impurity content in the paraffin wax. When the wax cools, the internal shrinkage of high quality paraffin wax 58 is more coordinated, creating a slight separation force between the wax and the mold, facilitating smooth demolding. Higher melting points of high quality paraffin wax 58 also mean higher hardness and a less sticky surface, making it good for producing upright, columnar, or sculpted candles. To make the surface of candles smoother, you can add a small amount of microcrystalline wax or stearic acid to the high quality paraffin wax 58 formula.

How to adjust the Fully Refined Paraffin Wax formula?

Choose the appropriate melting point paraffin wax: Different paraffin products can be used for candles of different shapes and processes. For example, to produce columnar candles, a fully refined paraffin wax with a melting point of 60–62°C can be used, as it is less prone to deformation; if producing container candles, a type with a melting point of around 58°C can be used to reduce wall peeling.

Add an appropriate amount of stearic acid (2–5%): Adding an appropriate amount of stearic acid to Fully Refined Paraffin Wax can improve lubricity, reducing damage to the candle body during demolding and making demolding easier.

Mix a small amount of microcrystalline wax (5–10%): Adding microcrystalline wax to Fully Refined Paraffin Wax can prevent the wax from cracking during cooling, while also enhancing its resistance to deformation, making demolding smoother.

One-Stop Candle Manufacturing Solution: From Fully Refined Paraffin Wax to Machinery

Junda Wax is not only a leading high quality paraffin wax 58-rated candle manufacturer in China, but also a global one-stop solution provider for candle manufacturing. We offer:

Paraffin Wax Raw Material Series: Fully refined paraffin wax, semi-refined paraffin wax, microcrystalline wax, plant wax;

Candle Dyes and Fragrances: Stable fragrance release, color that does not easily settle.

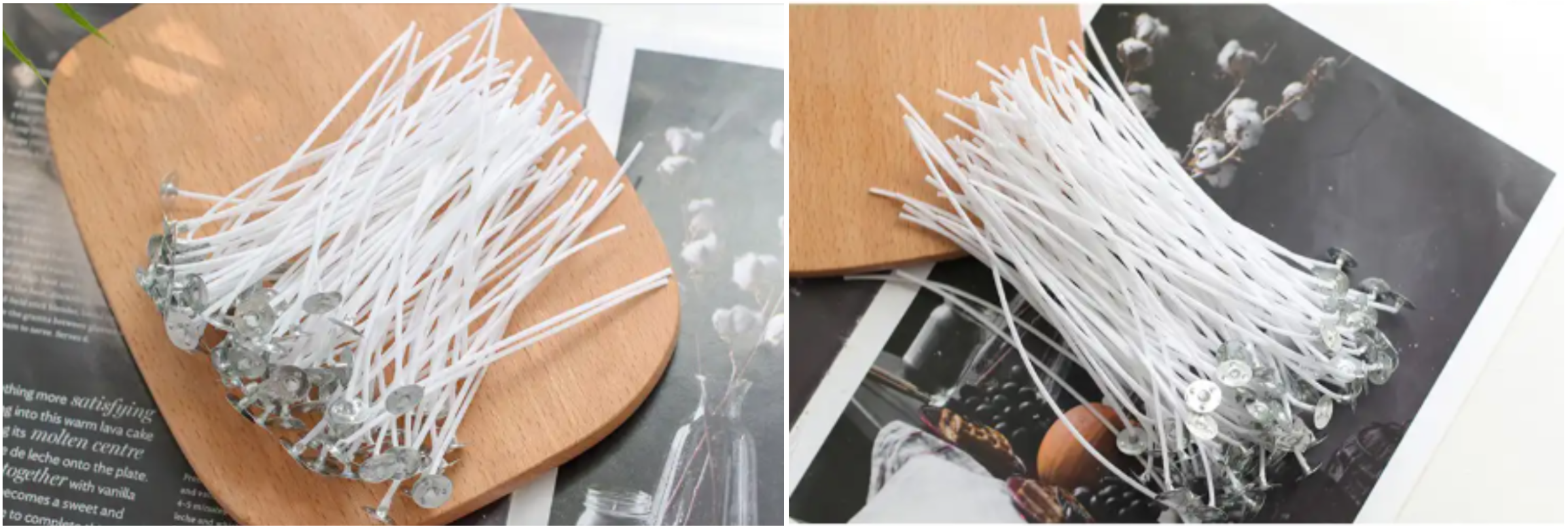

Wicks: Stable burning, custom length supported; (paper wicks, wood wicks, cotton wicks, etc. optional)

Candle Machinery and Equipment: Such as automatic wax injection machines, demolding machines, cooling systems;

OEM Customization Services: Junda can provide services including candle design, machine packaging solutions, and export.

Junda Wax has a production base in Fushun, Liaoning Province, with over 25 years of industry experience. We have long provided customized wax materials and equipment solutions to customers in the United States, Germany, Poland, and the Middle East, helping them achieve end-to-end integration from raw material procurement to automated production.

How to Maintain Consistency in Demolding During Mass Production?

In large-scale production, mold material, ambient temperature, and formula stability all affect demolding consistency. We recommend that companies:

Clean molds regularly after use to avoid wax residue;

Control the production workshop temperature between 20–25°C. Temperatures that are too high or too low can cause problems during candle demolding;

Use high-quality, stable high quality paraffin wax 58 raw materials. Junda Wax's Fully Refined Paraffin Wax is an excellent choice.

Junda's technical team can provide customized production formulas and demolding optimization suggestions based on customer needs, ensuring that products maintain the same texture and surface gloss under different production line conditions.

Junda Wax is committed to providing customers with full-chain support from paraffin wax, dyes, wax wicks to machinery, helping companies improve production efficiency and product competitiveness. We sincerely invite global partners to visit our factory and experience our R&D capabilities and one-stop candle production service. We look forward to establishing long-term cooperation with you. For further information, please contact RobyHuo@jundawax.com.

References

1.ASTM International. (2022). Standard Specification for Paraffin Wax for Candles (ASTM D6159).

2.National Candle Association (NCA). (2023). Candle Manufacturing Best Practices Report.

3.European Candle Manufacturers Association (ECMA). (2024). Annual Technical Bulletin: Wax Formulation and Mold Release.