The burning time of a candle may seem like a simple question of "how long it burns," but a deeper dive reveals a complex interplay of factors, including raw material structure, ignition point stability, heat conduction, wick absorption speed, container shape, pouring temperature, and fragrance system. Among these variables, Fully Refined Paraffin Wax has consistently been the most crucial and direct factor in extending burning time. For over a decade, we've exported Fully Refined Paraffin Wax to Europe, America, the Middle East, Africa, South America, and Southeast Asia, and almost all our clients have reported that Fully Refined Paraffin Wax is the truly worthwhile investment for longer-burning candles.

I. Why do all long-burning candles prefer Fully Refined Paraffin Wax?

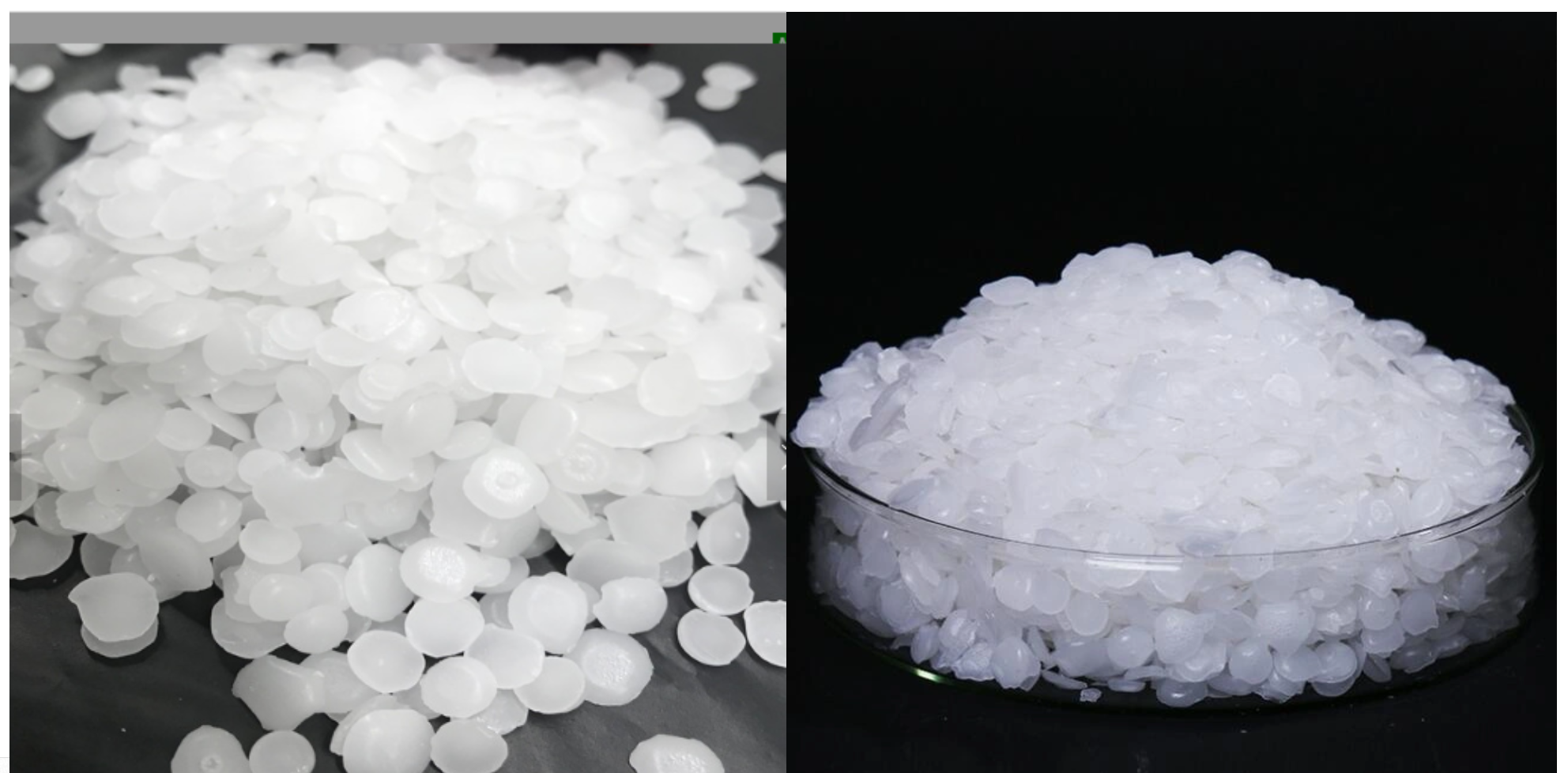

We often say "raw materials are fundamental," and this is absolutely true in the candle industry. The main reason Fully Refined Paraffin Wax significantly extends burning time is its exceptionally high purity and low oil content (typically ≤0.5%). This prevents the candle from wasting fuel through rapid melting or flickering flames. Kunlun paraffin wax has a more regular molecular structure and fewer impurities, resulting in higher energy efficiency during combustion. In other words, Kunlun paraffin wax doesn't waste heat on irrelevant impurities, focusing instead on ensuring stable burning. The lower oil content of Kunlun paraffin wax also means a more stable melting point; the molten pool won't flow erratically or deepen too quickly. This is especially important for cup candles, religious candles, and outdoor candles, as their core requirements are long burning time, stability, and durability.

II. Temperature Control: A Key Step in Utilizing Paraffin's Performance

Kunlun paraffin wax is highly temperature-dependent. To make Fully Refined Paraffin Wax burn longer, the melting temperature, feeding temperature, pouring temperature, and cooling temperature all need to be relatively stable. If the temperature is too high, the paraffin molecules will be damaged, the ignition point will drop, and the burning time will naturally shorten; if the temperature is too low, it will not melt easily, leading to bubbles, voids, and cracks in the finished product, resulting in uneven burning. Therefore, Junda Wax always recommends that factories—regardless of size—must have a constant temperature control function in their wax melting system.

Junda Wax's exported wax melting tanks generally support a temperature control accuracy of ±1℃ to help customers maintain consistency during mass production. Because as long as the temperature is stable, Kunlun paraffin wax's stable performance will be excellent.

III. Candle Containers Also Affect Burning Time

Many people believe that burning time is only related to the candle's material, but the shape, material, and thickness of the container also affect the performance of Fully Refined Paraffin Wax. For example, the same paraffin wax in a tall, narrow cup will burn longer than in a short, wide cup because the flame is less affected by air, resulting in a more concentrated molten pool. If you use a metal container, its faster heat conduction will cause it to burn faster than a glass container. Ceramic containers have good heat retention, which also makes the candle burn longer.

Many of our clients make "long-lasting emergency candles" or "religious candles," and they generally choose the container height and diameter based on the logic of burning longer. Because of this experience, Junda Wax can now recommend more suitable containers for clients, allowing Fully Refined Paraffin Wax's burning-long properties to be better utilized.

IV. The "Delicate Balance" of Additives, Fragrances, and Burning Time

If you are making unscented candles, you can fully utilize Kunlun paraffin wax's natural burning-long ability. However, if you are making scented candles, the proportion of fragrance must be carefully controlled. The more fragrance added, the shorter the burning time—this is common industry knowledge—because fragrance is essentially also fuel and will accelerate the melting of the wax. Kunlun paraffin wax's advantage lies in its excellent compatibility with fragrances. As long as the ratio is controlled within a reasonable range (generally 5%–8%), both fragrance and burnability are guaranteed.

When Junda Wax works on scented candle projects with clients in Southeast Asia and Western Europe, it often recommends fragrance-retaining additives to ensure the candles maintain a good burn time while still releasing their fragrance. This is why we consistently use Kunlun paraffin wax.

V. Don't Neglect Equipment – It Determines Your Ability to Produce Stable and Long-Lasting Candles

While Kunlun paraffin wax is excellent, achieving consistent performance requires suitable production equipment. Whether it's a constant-temperature melting tank, automatic stirring system, quantitative filling machine, automatic cup wax filling line, column wax shaping machine, or post-production labeling and packaging equipment, all these can significantly improve consistency. Especially for factories handling export orders, maintaining stability is almost impossible without automated equipment. Junda Wax has long exported candle machinery and equipment, and many of our startup clients, even those starting from scratch, have directly built their candle factories using our complete equipment + raw material solutions, enabling them to start production from cup wax and column wax to scented candles.

When the equipment is running stably, the high purity and stability of Kunlun paraffin wax natural wax truly translate into a longer burning time.

From paraffin wax to wicks to equipment, we provide a complete one-stop solution. Ultimately, making candles burn longer isn't due to a single factor, but rather the combined effect of raw materials, wicks, containers, temperature control, and equipment. Kunlun paraffin wax is not only a core ingredient for longer burning time, but also a standard component for many high-end candle brands and export factories. Junda wax not only exports high-quality kunlun paraffin wax, semi-refined paraffin wax, microcrystalline wax, and plant waxes, but also provides a complete set of raw materials including wicks, dyes, fragrances, containers, and molds. We can also provide complete candle machinery and equipment such as melting tanks, filling machines, and cup wax production lines, helping customers truly achieve a one-stop solution from "raw materials" to "production line."

If you are preparing to enter the candle industry or are looking for a more stable and longer-burning paraffin wax system, you are welcome to contact Junda wax at RobyHuo@jundawax.com, and we also welcome you to visit our factory. We will design the most suitable solution for you based on your product line and budget, so that every candle can burn more stably, cleaner and longer.